Case Studies

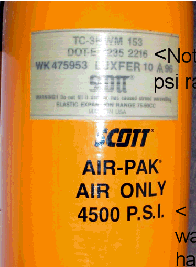

Brought in for visual by

mistake, used for smuggling. held

50 psi when assembled

mistake, used for smuggling. held

50 psi when assembled

Disaster waiting to Happen

Max 2216 psi

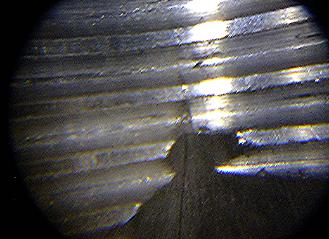

Walter Kidde 80cuft Sustained load

cracking. Cyl had 3000 psi in it 30

minutes before brought in for

Hydro

Same cyl, crack goes almost to top

of threads

Over .90 material missing over a 1

inch area all around the

circumference of the Cylinder

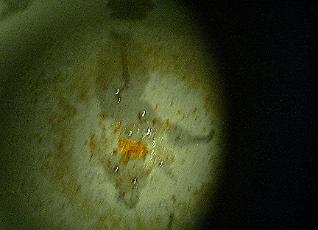

3600 psi bank bottle rotted all

around Cyl. This was in use

when damage was found.

Emergency bail out cylinder 300ft MOD

that has seen better days

Cylinder corrosion damage caused by

fresh water over long period of time

.120 deep pitting in crown of cylinder

2005 Aluminum cylinder with major

crack plus 4 additional cracks

Steel cylinder loaded with Silicone

paste all over inside.

Same cylinder showing silicone paste

globs on bottom

Aluminum 40 with disintegrated Viton

o-ring and heavy corrosion

Alum 40 O-Ring gland showing extremely

heavy oxidation/corrosion

Steel Cylinder all rusted inside

Same cylinder after our cleaning process

Steel PST Genesis 100. Hundreds of pits all over the cylinder found after cleaning out rust

Steel Cylinder all rusted inside